Common Questions When Choosing Timing Belt

Choosing a timing belt can seem like a daunting task; they're more complex than your standard conveyor belt. With multiple fabrication options, tooth profiles, dozens of backing/cover materials, and several belt layers, the whole process can be overwhelming.

Every timing belt application is unique; there's no one-size-fits-all model to follow. Timing belt solutions need to be determined on a case-by-case basis. To select the most efficient belt for your plant, you'll want an expert's opinion. That's why the professionals at Accurate Industrial created this guide: to answer our most commonly asked timing belt questions. Timing Belt Frequently Asked Questions:

1. How do I know when I need a truly endless belt vs. a welded endless belt?

The choice depends on the belt's application. If your application requires the belt to transmit power, you will need a truly endless belt. Welded endless belts are suitable for more common conveying applications, where they carry components, ingredients, finished products, cartons, etc. on top. The "timing" in timing belt indicates they are primarily used to synchronize the delivery of goods in production, packaging, or freight-loading processes.

2. What cord type should I use?

Different cord types are designed for different applications. Steel is typically the tensile cord material of choice, especially in power-transmission applications, providing the highest tooth shear strength. Kevlar cord is an effective alternative often used in metal detecting applications and where steel does not offer sufficient impact resistance for dropped items. Note that Kevlar cannot be used in wet or humid environments, as aramid fibers absorb moisture, causing them to stretch and contract, which can lead to performance issues such as slippage and binding.

3. What is PAZ/PAR and why do I need it?

PAZ/PAR are nylon fabric coverings molded to the back (PAR) or the tooth side (PAZ) of timing belts. The nylon facings reduce friction on both sides. PAZ optimizes the interactions between the timing belt teeth and the pulley, resulting in quieter operation and longer tooth life. PAR reduces friction between the timing belt and the conveyed product, which is especially useful in accumulating applications and for easy product release, speeding up operations.

4. What are the advantages and disadvantages of a pin splice?

Pin splicing allows belts to be removed and installed without disassembling the machine, enabling belt replacement in as little as 10 minutes, saving valuable production time. However, pin splicing reduces the belt's tensile strength, making it unsuitable for power-transmission applications. Note: welded endless belts are about half as strong as truly endless belts; pin-spliced belts are about half as strong as welded belts.

5. What is the difference between a molded cover and a spliced cover?

Molded covers offer superior performance, as failures often occur at splice locations. Molded covers are continuous and seam-free, preventing fraying or catching. However, some rubbers and materials cannot be molded and require spliced covers. The disadvantage of molded covers is the longer lead time for manufacturing and delivery, typically 4 to 6 weeks.

6. How do I find out my timing belt's tooth style?

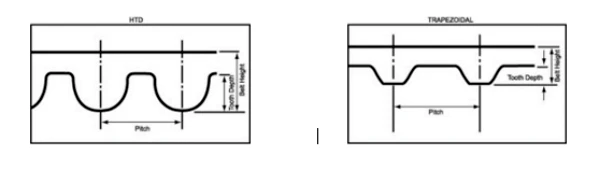

The best way to determine the tooth style is by using a timing belt tooth gauge; contact Accurate Industrial for your free gauge. Without a tooth gauge, you can determine the tooth style by observing the tooth shape (rounded or trapezoidal) and measuring the pitch (the distance between the centers of two adjacent teeth).

timing belt tooth

7. What type of cover (backing) is best for my application?

For a comprehensive discussion and comparison of all timing belt cover options, use this guide to determine the best cover/backing type for your specific application.

Use this guide to navigate the complexities of timing belt selection and ensure you choose the most efficient and effective solution for your needs.

| Cover Type | Application | Description |

| Red Linatex | Grip | These covers are recommended when grip or product pulling is needed. |

| PAR | Accumulation/release | PAR covers will reduce friction between the back of the timing belt and the product being conveyed. They are the best choice for accumulating applications. PAR can also be used to help product release from the back of the belt. |

| Urethane | Abrasion resistant | Urethane timing belt covers have great abrasion resistant characteristics for longer wear time. |

| Supergrip (rough top) | Incline/grip | Use these covers when grip or product pulling is needed. |

| Viton | High heat | This cover can handle product temperatures up to 525°F. |

| Foam | Compression | Popular in many labeling applications, foam; however, offers very poor abrasion resistance. |

| Dual Durometer | Compression & abrasion resistant | This cover's design layers two separate materials. First, a foam cover is adhered to the back of the timing belt. Then a Linatex or urethane cover is adhered on top of the foam. This cover combines the compression properties of foam with the abrasion resistant of rubber or urethane. |

Leave Me Your Requirement!