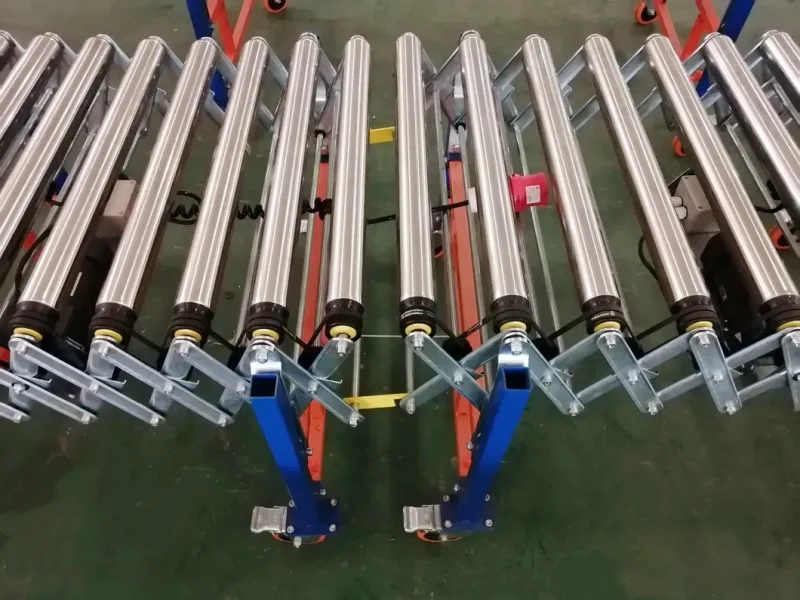

Powered Flexible Conveyor for Bulk Unit Handling

A powered flexible conveyor (also called a motorized flexible conveyor) is a versatile, extendable conveyor system designed to move cartons, boxes, or packages automatically — ideal for truck loading/unloading, warehouse dispatch areas, and parcel handling lines. Unlike gravity types, powered flexible conveyors use motor-driven rollers or belts to move goods without manual pushing, improving efficiency and ergonomics.

Technical Specifications (Typical Range)

| Parameter | Specification | Imperial Equivalent |

| Conveyor Width | 400–1000 mm | 16–40 in |

| Roller Diameter | 50–60 mm | 2–2.5 in |

| Load Capacity | 40–80 kg/m | 27–54 lbs/ft |

| Conveyor Speed | 10–30 m/min (adjustable) | 33–100 ft/min |

| Extended Length | 4–12 m | 13–40 ft |

| Adjustable Height | 700–1000 mm | 28–40 in |

| Motor Power | 0.4–1.5 kW | — |

| Frame Material | Powder-coated steel or stainless steel | — |

| Drive Voltage | 220V / 380V, 3-phase | — |

Galleries of Powered Flexible Conveyor

Key Features

- Self-powered movement – no manual pushing required

- Flexible design – extendable, retractable, and curve-capable

- Variable speed control (VFD) for precise handling

- Reversible direction (loading or unloading)

- Easy mobility with locking casters

- Safe operation – emergency stop switches and sensors

- Low noise and low maintenance

Applications

- Truck and container loading/unloading

- E-commerce warehouses (Amazon, Flipkart, etc.)

- Courier & parcel hubs (DHL, FedEx, UPS)

- Packaging and dispatch lines

- Food, FMCG, and pharmaceutical plants

Advantages over Gravity Type

| Feature | Gravity Flexible Conveyor | Powered Flexible Conveyor |

| Power Requirement | None (manual push) | Electric motor drive |

| Load Capacity | 20–100 kg/m | 40–80 kg/m |

| Speed | Depends on gravity/slope | Adjustable 10–30 m/min |

| Direction | One-way | Reversible |

| Ideal Use | Short manual transfer | Continuous automatic transfer |

| Cost | Lower | Higher (but more productive) |

Options & Accessories

- Photoelectric sensors for auto start/stop

- Zig-zag or S-shape layouts for flexible routing

- Integration with telescopic conveyors for truck docks

- Emergency stop cords along the length

- Side guards and guide rails for carton alignment

A powered flexible conveyor typically supports 40–80 kg/m (27–54 lbs/ft), offers variable speed (10–30 m/min), and can extend up to 12 m (40 ft) — making it ideal for automated carton handling and truck loading operations.

Would you like me to show a diagram or layout of a powered flexible conveyor system (e.g., connected from a packing line to a truck dock)?

Leave Me Your Requirement!