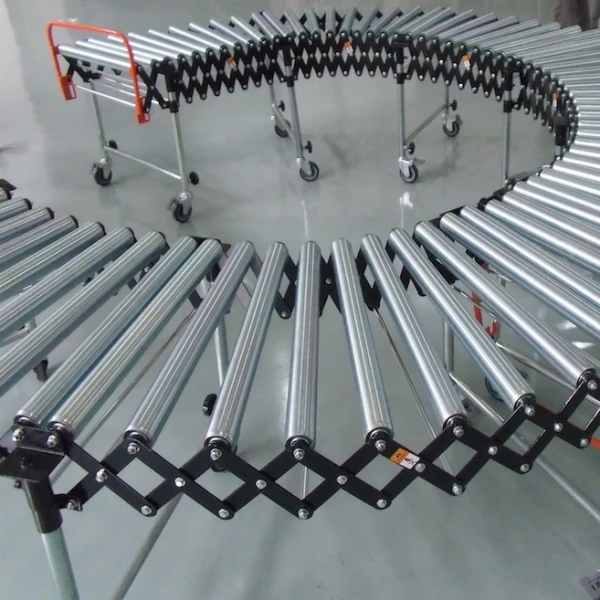

Flexible Roller Conveyor

Flexible Powered Roller Conveyor

Flexible Gravity Roller Conveyor

Applications

Truck Loading & Unloading

Feeding truck loading conveyors and Receiving packaged goods from truck unloading conveyor.

Container Loading Unloading

Feeding truck loading conveyors and Receiving packaged goods from truck unloading conveyor.

Warehouses Sotrage Processing

Tansfer packaged goods, Assist to unload and load packaged goods from trucks & containers.

Transferring in Assemble Line

Used for bulk packaged goods transferring in a manufacturing plant & packaging line.

More About Flexible Roller Conveyor

Inbelts is a flexible roller conveyors manufacturer in China. We strictly control the quality and production cost in the production. We are dedicated to providing professional and efficient services. A flexible roller conveyor system composed of multiple linked frames with rollers or skate wheels, supported by legs with swivel casters. The entire extendable roller conveyor unit can extend, curve, collapse, or be moved easily to adapt to different work zones.

Key Features of Flexible Roller Conveyor

| Feature | Description |

| Expandable Length | Can be compressed when idle and extended when in use |

| Flexible Layout | Curves around obstacles, loading bays, or corners |

| Swivel Casters with Locks | For easy relocation and stable operation |

| Height Adjustable Legs | Allows ergonomic height matching |

| Roller or Skate Wheel Options | Choose based on product weight and application |

| Optional Motorization | Powered versions available for driven transport |

Types of Flexible Roller Conveyors

| Type | Description | Typical Use |

| Gravity Roller | Non-powered; relies on gravity/manual push | Boxes, cartons, totes |

| Powered Roller | Motorized rollers move loads automatically | Heavy items, automation lines |

| Skate Wheel Conveyor | Light-duty flexible conveyor | Lightweight cartons, parcels |

| Plastic Roller Conveyor | For delicate or packaged food items | Food, pharma, light goods |

Typical Technical Specifications

| Parameter | Range / Options |

| Conveyor Width | 400 mm – 1000 mm |

| Extended Length | 3 – 20 meters (customizable) |

| Collapsed Length | ~30–50% of extended length |

| Roller Material | Steel, galvanized, PVC-coated, stainless, plastic |

| Load Capacity | 50 – 100 kg/m (gravity), higher for powered types |

| Roller Diameter | 38 mm, 50 mm, 60 mm (common sizes) |

| Height Adjustment | ~700–1000 mm via manual screw or gas spring legs |

| Frame Material | Mild steel, stainless steel, or aluminum alloy |

Applications of Flexible Roller Conveyor

| Industry / Area | Application Examples |

| Logistics & Warehousing | Parcel loading/unloading, dock feeding |

| E-commerce Fulfillment | Flexible picking lines, order sortation |

| Courier Terminals | Temporary sortation and truck unloading |

| Food & Beverage | Dry packaged food movement |

| Manufacturing | Component kitting, WIP movement |

| Retail Distribution | Temporary dispatch conveyor |

Gravity vs Powered Flexible Conveyors

| Feature | Gravity Conveyor | Powered Conveyor |

| Power Requirement | ❌ No | ✅ Yes |

| Cost | ✅ Lower | ⚠️ Higher |

| Ideal for | ✅ Light–medium loads | ✅ Heavy or long-distance loads |

| Speed Control | ❌ Manual | ✅ Controlled via inverter |

| Setup Complexity | ✅ Simple | ⚠️ More complex |

Customization Options

- Conveyor width, height, and length

- Roller pitch (spacing between rollers)

- Roller type: steel, PVC, plastic, anti-static

- Add-on guides, side rails, and stoppers

- Powered drive (optional for long units)

- Color coating, anti-rust finishes, SS304 for food use

Advantages of Flexible Roller Conveyor

- Compact storage when not in use

- Rapid deployment for variable work areas

- Enhances flexibility at shipping/receiving dock

- Cost-effective compared to fixed conveyors

- Easy to integrate into existing layouts

Would you like:

- A comparison of flexible roller vs telescopic conveyor?

- A specification sheet or layout drawing?

- Help sourcing suppliers or models for your application?

- Let me know your project needs or preferred usage scenario.

When considering the use of flexible roller conveyors, it's important to evaluate your specific material handling needs, the types of products you handle, and the layout of your facility. A well-designed flexible roller conveyor can contribute to a more efficient and streamlined material handling process in various industries. We can offer both powered flexible conveyor and flexible gravity conveyor for your projects.