Bag Loading Conveyor for Fast Bag Loading

A bag loading conveyor is a specialized conveyor system designed to load filled bags (such as cement, fertilizer, grain, sand, sugar, or chemical bags) onto trucks, containers, railcars, or into storage efficiently and safely. These bag loading systems often feature adjustable heights, extendable booms, and durable belts to handle loads up to 50 kg per bag or more.

Types of Bag Loading Conveyors

Fixed Bag Loading Belt Conveyor

A Fixed Bag Loading Belt Conveyor (short section) is a compact, stationary conveyor designed to transfer filled bags from a packing machine or conveyor to a nearby truck, palletizing station, or storage point. The fixed bag loading system often consists of belt conveyors and roller conveyor systems.

- Simple horizontal or inclined belt conveyor.

- Continuous transfer from bagging machine to truck or storage area.

- Low cost and easy installation.

- Adjustable belt speed.

- Suitable for medium loading distances.

Portable Bag Loading Conveyor

A Portable Bag Loading Conveyor is a movable belt conveyor designed for loading or unloading filled bags (e.g., cement, fertilizer, grain, sugar, sand, or chemical products) into trucks, containers, or rail wagons. The portable bag loading system often consists of portable belt conveyors and flexible roller conveyor systems.

- Mounted on wheels for easy movement between loading points.

- Truck or container loading at various locations.

- Adjustable height and angle (manual or hydraulic).

- Can be used for both loading and unloading.

- Available in electric or diesel drive.

- Belt width: 500–800 mm

- Length: 6–12 m

- Capacity: 50–300 bags/hour

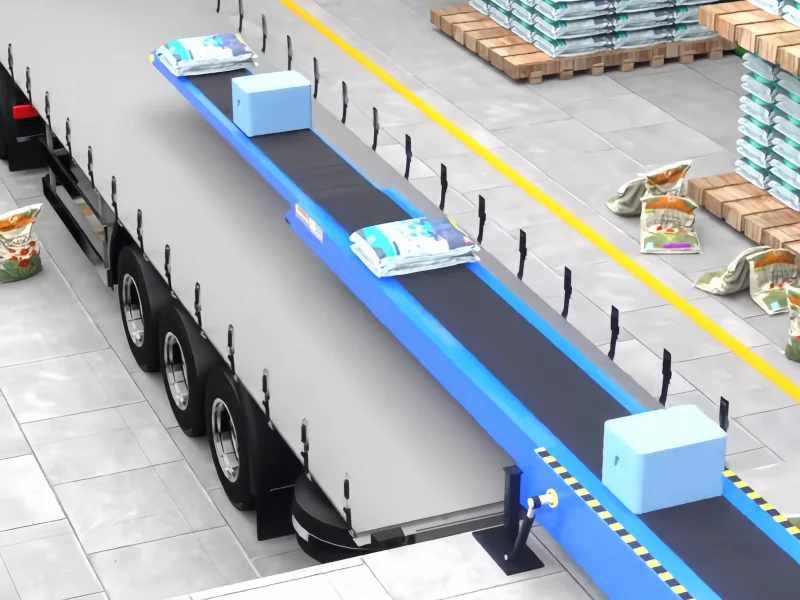

Telescopic Bag Loading Belt Conveyor

A Telescopic Bag Loading Belt Conveyor is an extendable, powered conveyor designed to load or unload filled bags directly into trucks or containers efficiently and safely. The telescopic bag loading system often consists of telescopic belt conveyors and flexible roller conveyor systems.

- Extendable sections (usually 2–4 stages) that move inside the truck or container.

- Warehouse or logistic centers for loading/unloading bags or boxes.

- Operator can extend/retract via control panel.

- Adjustable height for different truck levels.

- Greatly reduces walking and manual handling.

This is a telescopic belt conveyor for bag and carton boxes loading unloadng.

These are telescopic belt conveyor.

This is a hydraulic lifting conveyor with flexible roller conveyor syste.

Specifications of Bag Loading Conveyor

| Parameter | Range |

| Belt Width | 400 – 800 mm |

| Conveyor Length | 5 – 15 m |

| Conveying Capacity | 60 – 300 bags/hour |

| Inclination Angle | 0° – 25° |

| Drive Motor Power | 2 – 7.5 kW |

| Height Adjustment | Manual or Hydraulic |

| Mobility | Fixed or Portable (wheels) |

Applications of Bag Loading Conveyor

| Industry | Type of Bag | Conveyor Type |

| Cement Plant | 50 kg cement bags | Mobile or Telescopic |

| Fertilizer Plant | Urea / DAP bags | Mobile or Fixed Inclined |

| Food Industry | Rice, Sugar, Flour bags | Telescopic / Portable |

| Mining & Aggregates | Sand / Limestone bags | Heavy-duty Portable |

| Chemicals | Powder / Granules | Enclosed Belt Conveyor |

Key Components

- Rubber or PVC conveyor belt (anti-slip surface for bags)

- Electric motor and gearbox drive

- Height adjustment system (screw jack or hydraulic)

- Frame structure (mild steel or stainless steel)

- Mobility wheels or castors (for portable types)

- Control panel (forward/reverse, speed control, emergency stop)

Optional Accessories

- Bag flattening or aligning rollers

- Integrated weighing and counting system

- PLC-based automation for packing lines

Why to Choose Our Bag Loading Conveyor?

- Adjustable Design: Height and angle can be modified to align with truck beds or container floors, often ranging from ground level to 4-5 meters high.

- Capacity: Typically handles 1-50 kg per foot or bag, with options for higher loads in industrial models.

- Materials: Made from mild steel (MS), stainless steel, rubber belts, or PVC for durability and resistance to abrasion, heat, or oil.

- Efficiency Gains: Speeds up loading/unloading by 3-5 times compared to manual methods, reducing injury risks and downtime.

- Portability: Many models are mobile or wheeled for easy repositioning in warehouses or loading docks.

Would you like me to focus on a specific application, such as:

Truck loading conveyor for cement or fertilizer bags, or Telescopic belt conveyor for warehouse bag loading, so I can provide a sample technical drawing, capacity chart, and detailed specs (e.g., belt width, power, adjustable height range)?

Leave Me Your Requirement!