Carton Roller Conveyors for Carton Handling

A cartons roller conveyor is a type of material handling system specifically designed for transporting cartons, boxes, totes, and other rigid items smoothly and efficiently across short or long distances in warehouses, factories, and logistics centers.

Types of Carton Roller Conveyors

(1) Gravity Roller Conveyor

- Operation: Uses gravity or manual push for movement.

- Features: No power required; simple and cost-effective.

- Applications: Short-distance transport, sorting, or accumulation zones.

(2) Powered Roller Conveyor

- Operation: Driven by electric motors via belts, chains, or O-rings.

- Features: Continuous, controlled motion; suitable for automation.

- Applications: E-commerce fulfillment, parcel distribution, packaging lines.

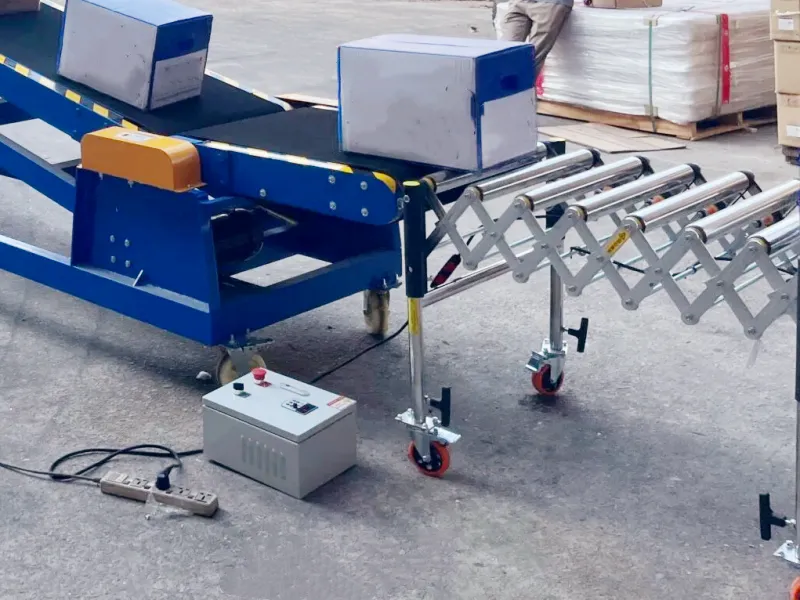

(3) Flexible / Expandable Roller Conveyor

- Operation: Can extend, contract, and curve easily.

- Features: Mobile, adjustable length and shape, ideal for temporary setups.

- Applications: Truck loading/unloading of cartons or boxes.

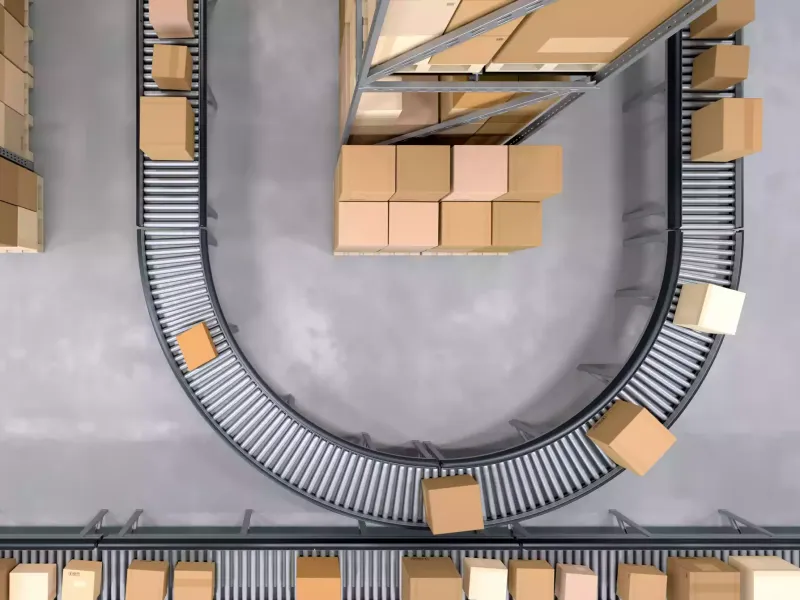

(4) Curved Roller Conveyor

- Operation: Uses angled rollers or tapered rollers for direction changes.

- Features: Smooth transitions between conveyor sections.

- Applications: Routing cartons between aisles or around corners.

Galleries of Carton Roller Conveyors

This is a flexible roller conveyor system for carton handling.

This is a fixed roller conveyor system for carton handling.

This is a curved roller conveyor for carton handling.

Components of Carton Roller Conveyor

- Conveyor Rollers: Available in steel (for heavy loads), aluminum (lightweight), or plastic (for lightweight or corrosive environments). Roller diameters range from 1.5 to 2.5 inches (38-63 mm) for cartons, with larger diameters for heavier loads.

- Frame: Typically steel or aluminum, providing structural support. Frames are powder-coated or galvanized for durability.

- Bearings: Sealed or precision bearings ensure smooth roller rotation and low maintenance.

- Drive System (for Powered Conveyors): Includes motors, belts, chains, or line-shaft drives. Common drive types are 24V DC or 230/460V AC motors.

- Supports: Adjustable legs or stands to set conveyor height (typically 24-36 inches for ergonomic handling).

- Accessories: Side guides, end stops, diverters, and sensors for flow control and safety.

Key Specifications

| Parameter | Typical Range |

| Roller Diameter | 38–60 mm |

| Roller Pitch | 75–150 mm |

| Conveyor Width | 300–1000 mm |

| Load Capacity | 20–100 kg/m |

| Conveyor Length | Customized |

| Frame Material | Carbon steel / Stainless steel / Aluminum |

Applications

- Logistics & warehousing centers

- E-commerce parcel handling

- Food & beverage packaging lines

- Postal and courier sorting

- Assembly lines in manufacturing plants

This is a carton roller conveyor system.

For specific details, such as conveyor sizing, roller types, or integration with other systems, please provide more context (e.g., carton size, facility layout, or throughput requirements), and I can tailor the response further!

Leave Me Your Requirement!