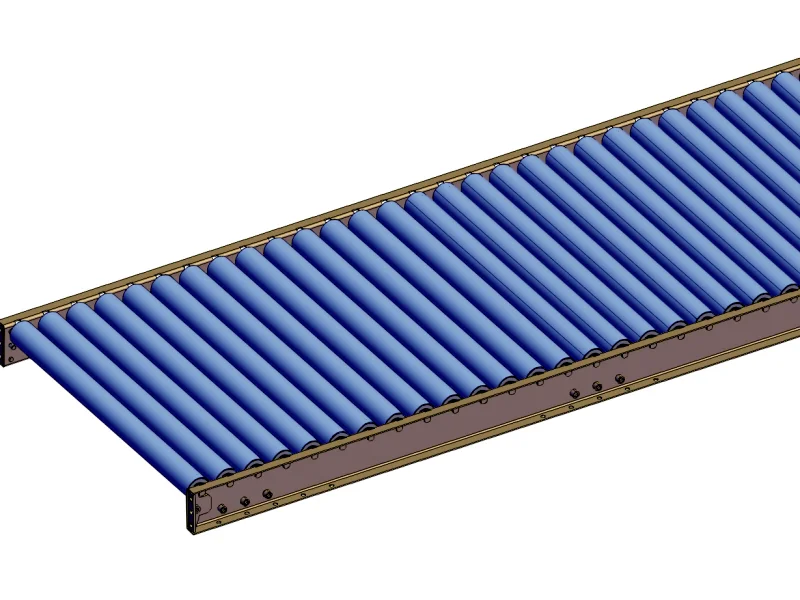

Heavy Duty Gravity Roller Conveyor

Our heavy duty gravity roller conveyors rely on gravity (via a slight incline) or manual push to move heavy loads, such as pallets or large industrial items, without powered motors, making them cost-effective and low-maintenance for specific applications. Below is a comprehensive guide on heavy-duty gravity roller conveyors, covering their design, components, selection process, pricing, etc.

What is a Heavy-Duty Gravity Roller Conveyor?

A heavy-duty gravity roller conveyor is a non-powered conveyor system designed to transport heavy loads—typically 500 to 5,000 lbs or more—using gravity or manual force. Rollers, mounted on a sturdy frame, allow loads to move along a slight incline (1–5°) or level surface. These roller conveyor systems are ideal for applications where powered systems are unnecessary or cost-prohibitive, such as short-distance transport, staging, or loading/unloading in warehouses or manufacturing facilities. They are robust, low-maintenance, and suited for heavy items like pallets, drums, or machinery parts.

Key Features

- Load Capacity: Supports heavy loads (500–5,000 lbs+), with large-diameter rollers (2.5"–3.5") and reinforced frames made of heavy-gauge steel or aluminum.

- Non-Powered: This type of unpowered roller conveyor relies on gravity (via incline) or manual push, eliminating electricity costs and motor maintenance.

- Durability: Built for rugged environments, with options like galvanized or stainless steel for corrosion resistance.

- Simplicity: Minimal moving parts (rollers, bearings) reduce complexity and upkeep

- Applications: Warehousing (pallet staging), manufacturing (assembly lines), distribution (loading docks), and heavy industrial tasks.

This is a section of gravity roller conveyor for easy packing.

Key Components

Gravity Rollers

- Function: Support and facilitate load movement; rotate freely on bearings.

- Specifications:

- Diameter: 2.5"–3.5" for heavy-duty (larger for greater capacity).

- Material: Steel (galvanized for rust resistance), stainless steel (food-grade), or reinforced plastic (rare).

- Length: Matches conveyor width (e.g., 48"–60" for pallets).

- Roller Spacing: 3"–6" centers; loads must span 3+ rollers for stability.

- Bearings: Heavy-duty, precision, or sealed for high loads and durability.

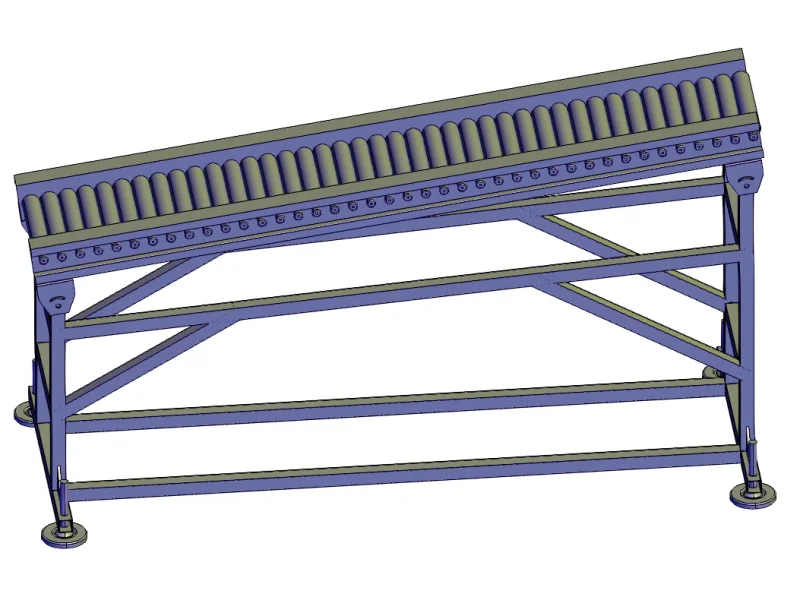

Conveyor Frame

- Function: Supports rollers and load weight; maintains structural integrity.

- Material: Heavy-gauge steel (powder-coated or galvanized), aluminum (lighter but less common), or stainless steel (washdown).

- Effective Width: Load width + 4"–6" margin (e.g., 48" pallet = 54" frame).

- Height: 12"–36" (low-profile for pallets, adjustable for alignment).

- Supports: Legs or stands every 5–10 feet, reinforced for heavy loads.

Side Rails

- Function: Guide loads, prevent derailment, and enhance safety.

- Types:

- Fixed: 4"–8" high, steel, for pallets or stable loads.

- Adjustable: For varying load sizes.

- Roller Guides: Rare, for delicate loads.

- Material: Steel, aluminum, or stainless steel.

Common Accessories

- End Stops: Prevent loads from rolling off (e.g., fixed or spring-loaded).

- Brakes/Dampers: Control speed on inclines for heavy loads.

- Floor Locks: Stabilize portable conveyors.

- Guides: Center loads on wide conveyors.

This is a gravity roller conveyor system with easy installing footprint.

Design Considerations

Load Capacity

- Range: 500–5,000 lbs (e.g., pallets, drums).

- Roller Rating: Each roller supports 500–2,000 lbs (e.g., 10 rollers at 1,000 lbs each = 10,000 lbs total).

- Frame Strength: Must exceed load weight (e.g., 5,000-lb load needs 6,000-lb frame rating).

Incline Angle

- Range: 1–5° (e.g., 1° = ~2" drop over 10'; 5° = ~10" drop).

- Heavy loads (e.g., 1,000 lbs+): 1–2° to control speed.

- Lighter loads (e.g., 500 lbs): 2–3° for momentum.

- Testing: Start shallow (1°) and adjust to avoid runaway or stalling.

Roller Spacing

- Rule: Loads span 3+ rollers (e.g., 48" pallet needs 12"–16" spacing).

- Typical: 3"–6" centers; closer for unstable or runner-based pallets.

Conveyor Layout

- Straight: Common for short runs (5'–50').

- Curved: Tapered rollers for turns (rare in heavy-duty gravity). We can offer gravity type curved roller conveyor system.

- Length: Modular sections (5' or 10') for flexibility.

Environment

- Dry/Indoor: Galvanized steel rollers/frames.

- Washdown/Food-Grade: Stainless steel, sealed bearings.

- Outdoor/Harsh: Galvanized or coated steel for corrosion resistance.

Safety Features

- Side Rails: 4"–8" high to prevent pallet derailment.

- End Stops: Mandatory to catch loads at the end.

- Brakes: For speed control on inclines with heavy loads.

How to Choose a Heavy-Duty Gravity Roller Conveyor

Define Application Requirements

- Load: E.g., 2,000-lb pallets (48" x 40") or 1,000-lb drums.

- Purpose: Staging, loading/unloading, or short transport.

- Distance: E.g., 10'–20' run.

- Flow: Gravity (incline) or manual push (level).

Select Roller Specifications

- Diameter: 2.5"–3.5" for heavy loads.

- Spacing: 3"–6" (e.g., 4" for 48" pallets).

- Material: Steel (standard), stainless steel (food-grade).

- Bearings: Heavy-duty or sealed for durability.

Determine Frame and Width

- Width: Load width + 4"–6" (e.g., 48" pallet = 54" conveyor).

- Frame: Heavy-gauge steel for strength; stainless steel for washdown.

- Height: 12"–18" for forklift access or 24"–36" for ergonomics.

Set Incline and Supports

- Incline: 1–2° for heavy loads (e.g., 2"–4" drop over 10').

- Supports: Every 5–10 feet, adjustable for incline.

Choose Side Rails and Accessories

- Side Rails: Fixed steel, 4"–6" high for pallets.

- End Stops: Heavy-duty to catch 2,000-lb+ loads.

- Brakes: Optional for speed control.

Factor in Environment

- Indoor: Galvanized steel.

- Food-grade: Stainless steel.

- Outdoor: Coated or galvanized components.

Budget and Maintenance

- Cost: $500–$3,000 per 10' section.

- Maintenance: Minimal; inspect rollers/bearings quarterly, clean as needed.

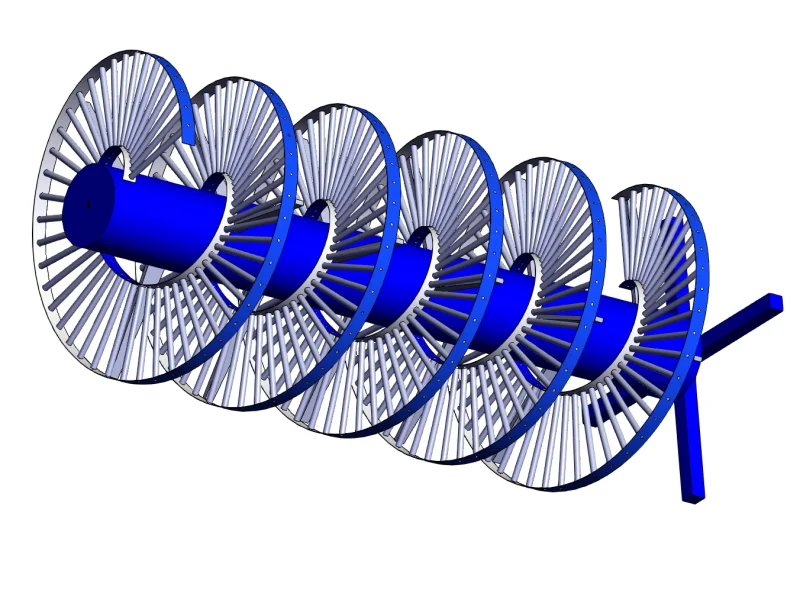

This is a spiral gravity roller conveyor for warehouse.

Pricing of Heavy Duty Gravity Roller Conveyor

Heavy-Duty Gravity Roller Conveyor:

- Standard (48"–60" wide, 2.5" rollers): $500–$2,000 for 10'.

- High-capacity (54"–72" wide, 3.5" rollers): $1,000–$3,000 for 10'.

- Example: 15' x 54" for pallets ≈ $1,500–$2,500.

Key Components:

- Rollers: Steel (2.5"): $10–$30 each; stainless steel (3.5"): $20–$50.

- Bearings: Heavy-duty, $5–$15 each.

- Frame Sections: Steel (10'): $200–$500.

- Side Rails: Steel (4"–6" high): $10–$20/ft; stainless steel: $15–$50/ft.

- End Stops: $10–$50 each.

- Brakes/Dampers: $50–$200 each.

- Spares: Budget $100–$300 for rollers, bearings, and rails per 10' section.

Maintenance Tips

- Rollers: Inspect bearings quarterly for noise or wear; replace if damaged.

- Frame: Check for dents or rust; clean in washdown environments.

- Side Rails: Ensure no loose bolts or damage; replace if bent.

- Incline: Verify angle (1–2°) for consistent flow; adjust if loads stall or run away.

- Spares: Keep rollers and bearings on hand for quick repairs.

This is a flexible gravity roller conveyor for easy and temporary layout.

Comparison with Heavy-Duty Powered Roller Conveyors

| Items | Gravity Type | Powered (Chain-Driven/Motorized) Type |

| Pros | Low cost ($500–$3,000), no electricity, minimal maintenance, simple design. | Precise control, handles long distances, supports automation, no incline needed. |

| Cons | Limited control (incline-dependent), not suited for long distances or automation, manual push required on level surfaces. | Higher cost ($3,000–$15,000), electricity and maintenance costs. |

| Best For | Short runs, staging, loading/unloading, cost-sensitive applications. | Continuous transport, heavy automation, complex layouts. |

| Our Offering | We can offer gravity roller conveyor and flexible gravity roller conveyor system. | We can offer powered roller conveyor and flexible powered roller conveyor system. |

Example Specification

15' heavy-duty gravity roller conveyor for 2,000-lb pallets (48" x 40").

- Width: 54" (48" + 6").

- Rollers: 2.5" steel, 4" spacing (pallet spans 12 rollers).

- Frame: Heavy-gauge steel, 18" height (forklift-friendly).

- Incline: 1.5° (~3.5" drop over 15').

- Side Rails: Fixed steel, 6" high.

- Accessories: End stop, floor locks.

- Cost: $1,500–$2,500 (conveyor); $150–$300 (spares: 5 rollers, 10 bearings, 5' rail).

Heavy-duty gravity roller conveyors are cost-effective, durable solutions for moving heavy loads (500–5,000 lbs) over short distances, costing $500–$3,000 per section. Key components include 2.5"–3.5" steel rollers, heavy-gauge frames, and side rails. They're ideal for pallet staging or loading/unloading in rugged environments. If you need a specific design, component focus (e.g., roller sizing), or pricing for a particular setup, share details (e.g., load, length, application), and I'll refine the response!

Leave Me Your Requirement!