PVC Conveyor Belts

PVC (Polyvinyl Chloride) conveyor belts are a widely used type of thermoplastic conveyor belt made with PVC compound as the top cover. These belts are designed for light- to medium-duty conveying applications across a variety of industries. PVC belts are known for their affordability, chemical resistance, smooth or patterned surfaces, and are non-toxic, making them suitable for food processing, logistics, pharmaceuticals, and general industrial use.

Corrugated Sidewall PVC Belts

Inbelts has a wide variety of corrugated sidewall PVC belt options to maximize your product yield and keep loss at a minimum.

PVC Cleated Belts

The PVC cleated belts can realize high angle conveying. The conveyor using cleated belts only needs a small space.

Food Grade PVC Belts

The food grade PVC conveyor belts are types of Synthetic Belts. Our FDA PVC conveyor belt can contact food directly.

PVC Conveyor Belts for Marble

The marble PVC conveyor belts are pattern belts. We provide saw tooth, low grip, dot top, grip, and Matt pattern belts.

Patterned PVC Conveyor Belt

Inbelts can supply PVC conveyor belts with different patterns like diamond, rough top, saw tooth, grip, etc.

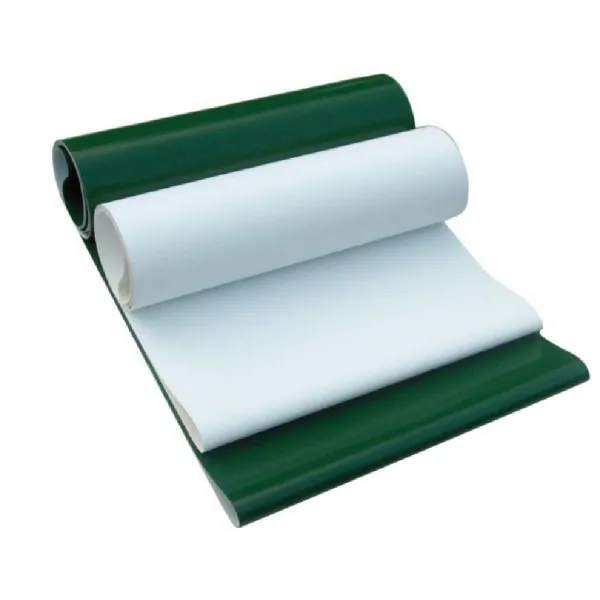

Normal PVC Conveyor Belts

The normal PVC conveyor belts are widely used in multi-industries. The surface is smooth or matt finish.

Features

Inbelts provides conveyor belts and belt conveyors for different industries like food process, tobacco, logistics, airport, printing, electronics, fitness equipment, wood process, stone and marble process, etc.

Temperature resistance

Inbelts cam custom belts with required minimum and maximum operating temperatures.

Cold Resistance

Inbelts can produce cold resisitance PVC conveyor belts with required low temperature environment.

Oil Resistant

Inbelts can produce oil resitant PVC conveyor belts for food industry or other industry have same requirement.

Custom Fabrication

Inbelts custom fabrication PVC conveyor belts with different technical and appearance specifications.

More About PVC Belts

A Polyvinyl Chloride Belt is a thermoplastic conveyor belt made from PVC compound and reinforced with synthetic fabrics such as polyester or nylon. It is one of the most common and cost-effective conveyor belt types used in light to medium-duty industrial applications, including food processing, logistics, packaging, and general manufacturing.

Structure of a PVC Conveyor Belt

A typical PVC conveyor belt consists of:

| Layer | Material | Function |

| Top Cover | PVC compound | Provides wear surface and protection |

| Fabric Layer(s) | Polyester (EP), Cotton, or Nylon | Strength and dimensional stability |

| Bottom Cover | PVC or fabric (optional) | For traction, grip, or sliding purposes |

Multi-ply options (1–4 plies) provide different levels of strength and flexibility.

Key Features of PVC Conveyor Belts

| Feature | Details |

| Material | Polyvinyl Chloride |

| Temperature Range | -10°C to +80°C (standard) |

| Surface Types | Smooth, rough top, diamond, crescent, or matte finish |

| Hardness | 60–80 Shore A |

| Tensile Strength | 120–400 N/mm depending on ply and thickness |

| Color Options | White, Green, Blue, Black, Transparent |

| Food Grade Options | Yes (FDA/EC-compliant PVC available) |

| Oil/Grease Resistance | Moderate (depending on PVC compound) |

| Flame Retardant Options | Yes (optional grades available) |

Applications of PVC Conveyor Belt

| Industry | Common Use Cases |

| Food Processing | Bakery, confectionery, meat & poultry, dairy |

| Logistics / Courier | Parcel sortation, distribution centers, airports |

| Pharmaceutical | Pill packaging, cleanroom environments |

| Textiles | Yarn and fabric transport |

| Electronics | Assembly lines for small parts |

| General Manufacturing | Parts conveying, machine integration, cutting lines |

Common Specifications

| Parameter | Range / Options |

| Thickness | 1 mm – 6 mm |

| Ply Structure | 1-ply, 2-ply, 3-ply, 4-ply |

| Roll Widths | Up to 3,000 mm (custom widths available) |

| Length | Cut-to-length or in roll form |

| Top Surface Finish | Smooth, Matte, Rough Top, Diamond, etc. |

Types of PVC Conveyor Belts

| Type | Description |

| Smooth PVC Belt | For general conveying; easy to clean |

| Rough Top PVC Belt | For incline/decline transport; added grip |

| Anti-static PVC Belt | For electronics or explosive environments |

| Flame-retardant PVC | For underground or safety-critical applications |

| Food Grade PVC Belt | Compliant with FDA/EC food safety standards |

| Cross-rigid PVC Belt | With lateral stability for sidewall or cleated conveyor systems |

PVC vs PU Conveyor Belts

| Property | PVC Belt | PU (Polyurethane) Belt |

| Cost | ✅ Lower | ⚠️ Higher |

| Flexibility | ⚠️ Moderate | ✅ Excellent |

| Abrasion Resistance | ⚠️ Good | ✅ Very Good |

| Food Safety | ⚠️ Good (but limited) | ✅ Excellent (FDA/EC certified) |

| Temperature Range | ⚠️ Limited (up to 80°C) | ✅ Wider (-20°C to 100+°C) |

| Cleaning | ✅ Easy | ✅ Easy |

Customization Options of PVC Conveyor Belt

- Thickness and number of plies

- Color and surface pattern

- Perforations, sidewalls, cleats, guides

- Anti-static, flame-retardant, food-grade properties

- Seamless endless belt or mechanical joint options

Would you like help:

- Choosing the right PVC belt for your application?

- Getting a specification sheet or manufacturer recommendation?

- Comparing it with PU, rubber, or modular belts?

Let me know what you're working on!

Industries

Inbelts provides conveyor belts and belt conveyors for different industries like food process, tobacco, logistics, airport, printing, electronics, fitness equipment, wood process, stone and marble process, etc.