High Efficient Trailer Unloading Conveyor

A trailer unloading conveyor is a type of conveyor system designed to efficiently unload carton boxes, packages, pallets, and more bulk units from trailers, trucks, or containers. They come in various types, from portable ergonomic models to fully automated chain or telescopic systems.

Types of Trailer Unloading Conveyor

| Type | Description | Key Features |

| Telescopic/Extendable Conveyors | Adjustable-length telescopic belt conveyors or exetendable roller conveyors that extend into the trailer to reach deep inside. | Variable extension (up to 50+ ft), powered or gravity-assisted, integrates with dock systems. |

| Portable Ergonomic Conveyors | Mobile, lightweight units (e.g., Destuff-it or Adjustoveyor) that workers can position manually. | Height-adjustable, self-propelled, reversible belts for loading/unloading; reduces lifting. |

| Chain Conveyor Systems | Heavy-duty chain roller conveyors for palletized loads, installed directly in trailers. | Low-weight, fast ROI; works in cold storage; handles standard pallets. |

| Gravity Roller Conveyors | Foldable, non-powered gravity roller conveyor that use incline/gravity for movement. | Portable, rust-proof stainless steel; customizable lengths/widths (up to 330 lbs load). |

| Automated Trailer Loaders | Fully integrated systems (e.g., Power Pack) for rapid full-trailer processing. | Loads/unloads entire trailers in ~1 minute; Just-In-Time compatible. |

Hydraulic lifting truck loading unloading conveyor working with flexible roller conveyor

Telescopic belt conveyor for trailer loading unloading

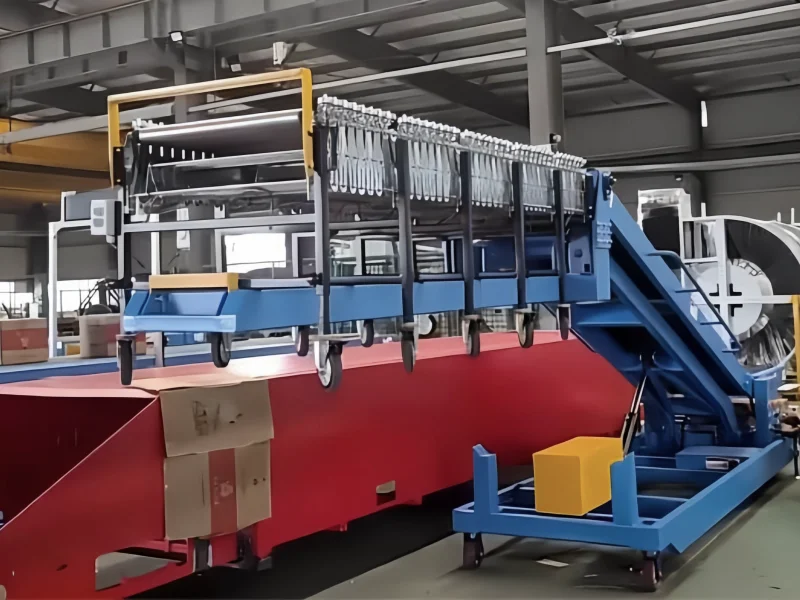

Telescopic belt conveyor with operation platform

Common trailer loading unloading conveyor in bulk unit handling

Components of Trailer Unloading Conveyor

- Conveyor belt or roller frame

- Adjustable height frame (manual or hydraulic)

- Drive motor and gearbox

- Control system (start/stop, speed, reverse, plc, automation)

- Mobility system (casters, wheels)

Applications of Trailer Unloading Conveyor

- High-volume shipping/receiving docks for boxes and cartons.

- Floor-loaded cargo in warehouses; cuts labor costs and injury risk.

- Pallet transport in manufacturing or cold chain logistics.

- Light-duty tasks like unloading express packages or tires in small operations.

- Automotive (e.g., engines, seats) and high-speed distribution.

Optional Customizations

- Telescopic extension (1–4 stages)

- Variable speed control (VFD)

- Reversible conveying direction

- Side guards or covers

- Integrated weighing or counting systems

- Dust control enclosure for bulk unloading

Why to Choose Trailer Unloading Conveyor?

- Efficiency: Speeds up processes, allowing more trailers per dock shift and reducing detention fees.

- Safety: Ergonomic designs minimize repetitive motions and heavy lifting, lowering injury rates.

- Versatility: Options for powered, manual, or hybrid setups; suitable for varying trailer heights and cargo types.

- Cost Savings: Quick ROI through labor reduction (up to 50%) and minimal maintenance needs.

Would you like me to focus on a specific type — for example:

Telescopic belt conveyor for warehouse trailer unloading, or Truck unloader conveyor for bulk units? I can then give you technical specifications, layout drawings, and typical parameters (belt width, roller width, length, etc.) for that type.

Leave Me Your Requirement!