Inbelts is a roller conveyor manufacturer in China. We offer gravity roller conveyor, powered roller conveyor, unpowered roller conveyor, curved roller conveyor, and pallet roller conveyor for sale. Our roller conveyors are widely used in warehouses, distribution centers, manufacturing facilities, and logistics operations.

Our Roller Conveyors for Sale

Pallet Roller Conveyor

A pallet roller conveyor is a heavy-duty roller conveyor specifically designed to transport pallets—flat structures used to carry goods—across various industrial settings.

Accumulation Roller Conveyor

An accumulation roller conveyor is a specialized type of roller conveyor designed to allow items to stop and accumulate at specific points along the roller conveyor system.

Powered Roller Conveyor

A powered roller conveyor is a type of roller conveyor that uses an external power source, typically an electric motor, to drive the rollers and move items along the system.

Unpowered Roller Conveyor

An unpowered roller conveyor is a material handling system that relies on manual force to move items along a series of free-spinning rollers, without the use of power sources.

Gravity Roller Conveyor

A gravity roller conveyor is a type of roller conveyor that uses the force of gravity to move items along a series of rollers, typically mounted on a slightly inclined frame.

Curved Roller Conveyor

A curved roller conveyor is a type of roller conveyor that has a curve in its layout, allowing goods to change direction (e.g. 30°, 45°, 90° or 180°) as they move along the system.

Common Driving Types of Roller Conveyors

Belt Driven Roller Conveyor

Belt-driven roller conveyors use belts (typically flat or round) to transmit power from a motor to rollers, offering a quieter and smoother alternative to chain-driven systems.

Motor Driven Roller Conveyor

Our motor driven roller conveyors use rollers with internal motors or external motors to drive the rollers, offering precise control, energy efficiency, and suitability for automation.

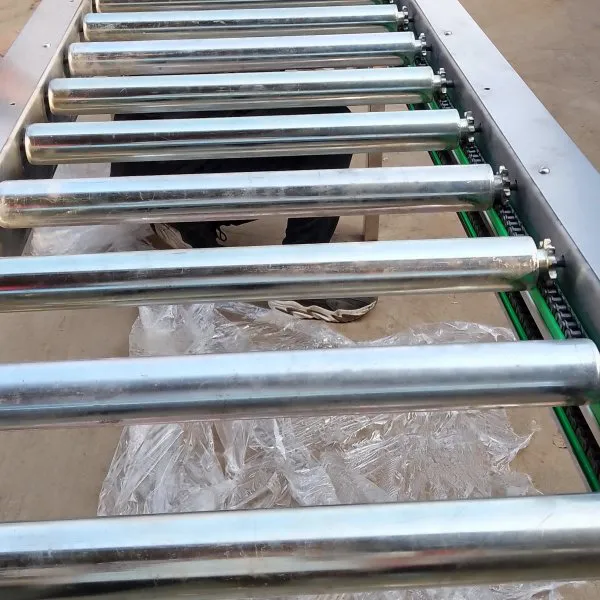

Chain Driven Roller Conveyors

Chain driven roller conveyors are robust and ideal for heavy-duty tasks like pallet handling or industrial transport, using roller chains to transmit power from a motor to rollers.

More About Roller Conveyors

A roller conveyor, also named roller conveyor table, is a system designed to transport items, commonly used in warehouses, manufacturing plants, and distribution centers. It consists of a series of rollers mounted on a frame, allowing items to move smoothly from one point to another. Roller conveyors can be either powered or gravity-fed, depending on the specific requirements of the operation. According to the weight of the transported materials, it can be divided into light, heavy and heavy-duty roller conveyors.

Driven Types of Roller Conveyors

- Gravity Driven: Rollers move items by gravity or manual push. Best for lightweight loads or short distances on a decline.

- Belt-Driven : A continuous belt (e.g., flat or V-belt) runs beneath the rollers, driving them via friction. Best for medium loads.

- Chain-Driven: Chains connect rollers, typically via sprockets, driven by a motor. Ideal for heavy loads or harsh environments.

- Motorized Roller (MDR): Each roller (or select rollers) has an internal motor, powered by low-voltage electricity. Used in zero-pressure accumulation systems and modern automated setups.

- Line Shaft: A single rotating shaft runs along the conveyor, connected to rollers via belts or bands. Best for light/medium loads.

Key Components of Roller Conveyors

- Conveyor Rollers: Cylindrical tubes made from metal (carbon steel, stainless steel), plastic, or composite materials. They vary in diameter and spacing based on load requirements.

- Conveyor Frame: Structural support (steel, aluminum) that holds rollers in place.

- Drive System: Powered Motors with belt, chain, or line-shaft mechanisms; Motorized Drive Rollers (MDR) have integrated motors.

- Non-Powered: Relies on gravity (declined) or manual force.

- Bearings/Ends: Enable smooth roller rotation.

- Controls: Variable speed drives, sensors, PLCs for automation.

Advantages of Roller Conveyors

- Efficient Straight-Line Transportation: Roller conveyors excel at moving goods in a straight path, making them highly efficient for transporting items between fixed points, such as workstations or across a warehouse.

- Simple Installation and Maintenance: Their straightforward design makes roller conveyors easy to install and maintain. Gravity-fed systems, in particular, have fewer moving parts, reducing the need for frequent upkeep.

- High Load Capacity: Designed to handle heavy items like pallets, large boxes, and industrial equipment, roller conveyors—especially those with steel rollers—are ideal for heavy-duty applications.

- Versatility in Design: These conveyors can be customized with adjustable roller spacing, height, and optional features like curves, allowing them to adapt to various facility layouts.

- Reduced Manual Handling: By automating the movement of goods, roller conveyors decrease the need for manual labor, lowering labor costs and reducing the risk of worker injuries.

- Low Operational Costs: Once installed, gravity-fed roller conveyors have minimal operational costs due to their simplicity and lack of power requirements.

- Energy Efficiency (Gravity-Fed Systems): Gravity roller conveyors rely on gravity rather than electricity, making them a cost-effective and energy-efficient option for short-distance movement.

How to Choose Roller Conveyor?

Choosing the right roller conveyor depends on various factors, including load type, weight, environment, and operational requirements. Here's a step-by-step guide to help you select the best roller conveyor for your needs:

1. Determine the Load Type & Weight

- Light Loads (Cartons, Small Boxes) → Gravity Roller or Belt-Driven Conveyor

- Medium Loads (Crates, Totes) → Powered Roller Conveyor

- Heavy Loads (Pallets, Metal Parts) → Chain-Driven or Pallet Roller Conveyor

2. Select the Roller Type & Material

- Steel Rollers – Best for heavy loads and industrial environments.

- Plastic Rollers – Suitable for lightweight applications and corrosive environments.

- Rubber-Coated Rollers – Provides grip and reduces noise.

- Stainless Steel Rollers – Ideal for food processing and wet environments.

3. Choose Between Powered vs. Gravity Roller Conveyor

- Gravity Roller Conveyor – Uses slope or manual push, best for simple movement of goods.

- Powered Roller Conveyor – Uses motors to move loads automatically, ideal for high-volume operations.

4. Consider Roller Spacing & Diameter

- Roller Spacing: The spacing should be ≤ 1/3 of the shortest load length to ensure stability.

- Roller Diameter - Small (20-40mm) – For lightweight items.

- Roller Diameter - Medium (40-80mm) – For general industrial use.

- Roller Diameter- Large (80-150mm) – For heavy-duty applications.

5. Select the Frame Material

- Mild Steel – Strong and cost-effective for general use.

- Aluminum – Lightweight and corrosion-resistant.

- Stainless Steel – Best for food, pharmaceutical, and corrosive environments.

6. Consider Environmental & Operational Factors

- Wet/Dusty Environment? → Use sealed bearings and stainless steel rollers.

- Temperature Sensitivity? → Ensure rollers and materials can handle extreme temperatures.

- Noise Control? → Use rubber-coated rollers or precision bearings.

7. Determine Additional Features

- Accumulation System – Stops or holds loads without back pressure.

- Side Guides & Guardrails – Prevents products from falling off.

- Speed Control – Regulates conveyor speed for smooth operation.

- Adjustable Height – Allows flexibility in different setups.

Would you like assistance in selecting a roller conveyor for a specific application?

Applications

Truck Loading & Unloading

Our roller conveyors can be used transfer goods and link telescopic belt conveyor for truck loading unloading.

Container Loading Unloading

Our roller conveyors can be used transfer goods and link telescopic belt conveyor for container loading unloading.

Warehouses Sotrage Processing

Roller conveyors are essential for moving packages, boxes, and pallets efficiently within warehouses.

Transferring in Assemble Line

In manufacturing plants, roller conveyors transport parts and products between different stages of production.

Industries

- Post

- Home Appliances

- Food

- Tobacco

- Light Industries

- E-Commerce

- Retail Stores

- Manufacturing & Packaging