Heavy Duty Powered Roller Conveyor

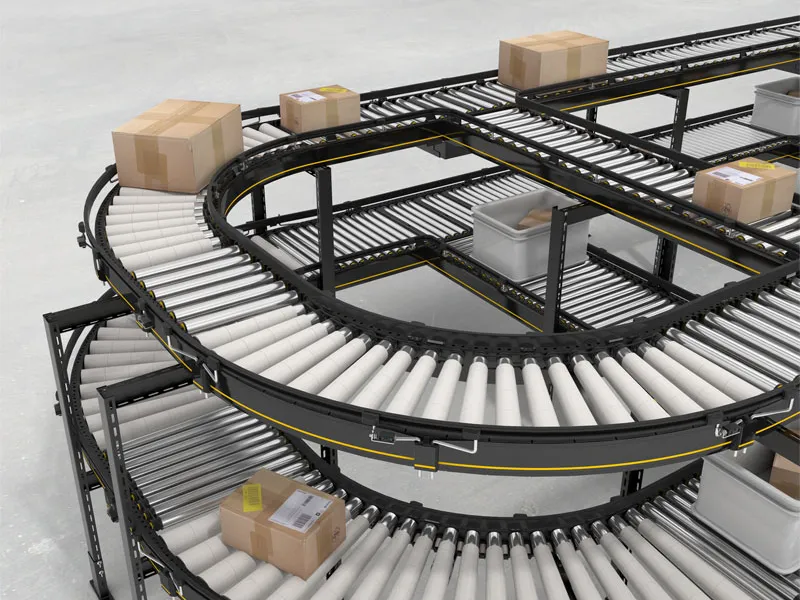

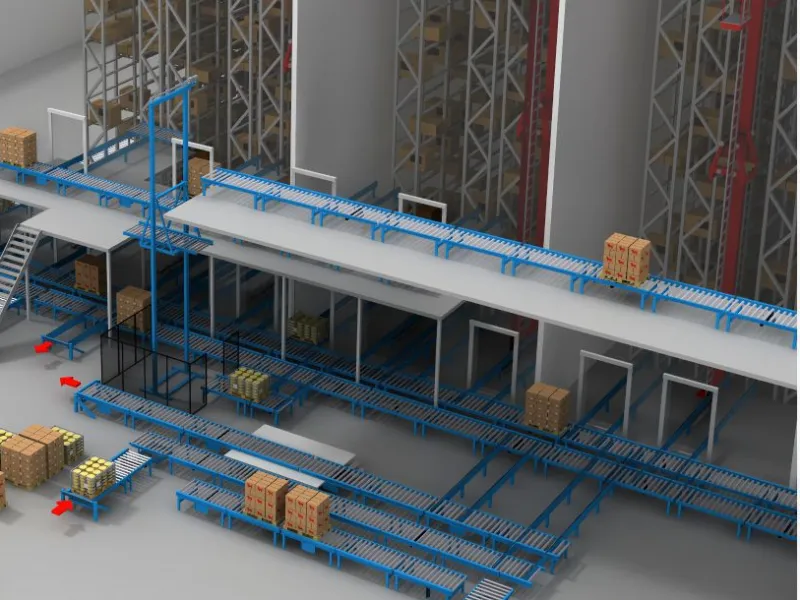

A heavy-duty powered roller conveyor is a robust conveyor system designed to transport large, heavy loads—typically ranging from 500 to 5,000 lbs or more—in industrial environments. Unlike gravity conveyors, these systems use motor-driven rollers to provide precise control over the movement of items such as pallets, machinery, or bulk materials. They are widely used in settings like manufacturing plants, warehouses, and distribution centers where efficiency, durability, and safety are critical.

Key Features of Heavy Duty Powered Roller Conveyor

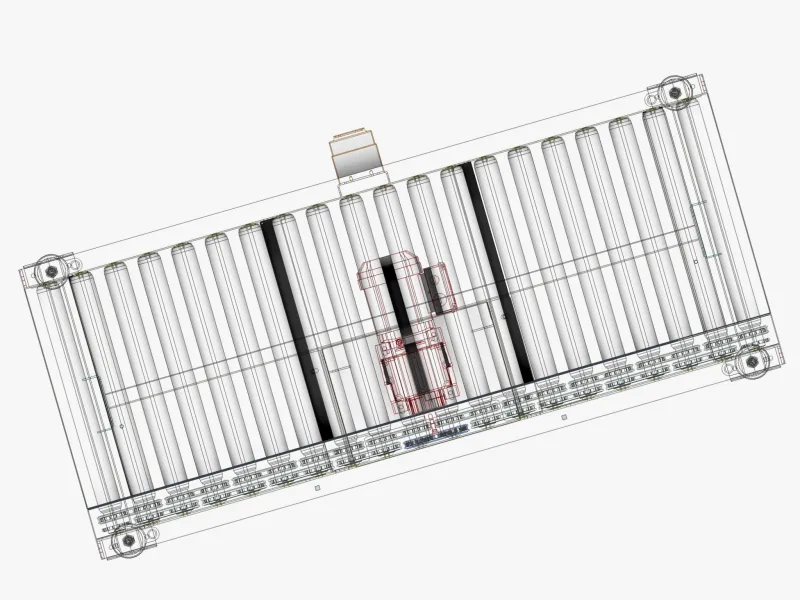

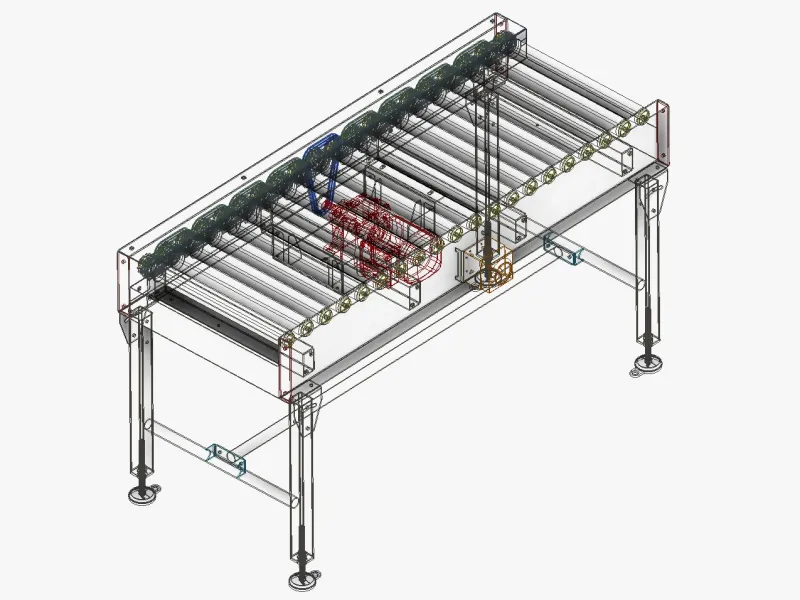

- Load Capacity: Built to handle heavy loads (e.g., pallets up to 5,000 lbs), with rollers typically 2.5"–3.5" in diameter made from steel or reinforced materials. Frames are constructed from heavy-gauge steel or aluminum for strength.

- Motor Types:

- Electric: Common, with 1–5 HP motors (110V–480V) for consistent power.

- Hydraulic: Used for high torque in specialized applications.

- Pneumatic: Rare, suited for environments with compressed air needs.

- Drive Mechanisms:

- Chain-Driven: Chains connect rollers for high-torque, reliable operation—ideal for heavy pallets. Our chain driven roller conveyor can meet medium and heavy duty conveying requirement of bags, pallets, boxes, cartons, etc.

- Belt-Driven: Uses belts for smoother, quieter movement, though less common for heavy-duty tasks. Our belt driven roller conveyor can convey light and medium duty goods like bags, cartons, etc.

- Motorized Rollers (MDR): Rollers with internal motors (e.g., 48V DC) for precision, typically for lighter loads. Our motor drive roller conveyors can handle light duty goods like bags, packages, cartons, etc.

- Speed and Control: Adjustable speeds (30–150 ft/min) via variable frequency drives (VFDs) or programmable logic controllers (PLCs), with options for zoned accumulation or merging.

- Durability: Reinforced components resist harsh conditions (e.g., dust, impact), with options like galvanized or stainless steel for corrosion resistance.

Benefits of Heavy Duty Powered Roller Conveyor

- Efficiency: Automates movement of heavy loads, reducing cycle times and increasing throughput.

- Labor Savings: Minimizes manual handling or forklift use, cutting labor costs.

- Safety: Reduces worker exposure to heavy lifting, with features like guards and emergency stops.

- Versatility: Handles inclines, declines, and curves, with adjustable speeds for various loads.

Applications of Heavy Duty Powered Roller Conveyor

Heavy-duty powered roller conveyors are essential in industries such as:

- Manufacturing: Moving components or finished goods between production stages.

- Warehousing and Distribution: Transporting pallets to storage or shipping areas.

- Automotive: Handling heavy parts like engines or chassis.

- Food and Beverage: Moving bulk goods in sanitary-compliant designs.

- Mining: Transporting abrasive materials in rugged conditions.

Customization Options of Heavy Duty Powered Roller Conveyor

These conveyors can be tailored to your needs:

- Roller Size/Spacing: Larger rollers (e.g., 3.5") for heavy loads; closer spacing for stability.

- Frame Materials: Steel for strength, aluminum for lighter setups, or stainless steel for washdown environments.

- Motor and Drive: Sized and selected (chain, belt, or MDR) based on load and speed requirements.

- Controls: Basic on/off, VFD for speed, or PLC with sensors for automation.

- Accessories: Side rails, accumulation zones, or diverters.

Maintenance Requirements of Heavy Duty Powered Roller Conveyor

To ensure longevity:

- Inspections: Check rollers, chains/belts, and motors monthly for wear or damage.

- Lubrication: Lubricate chains every 100–500 hours; grease bearings as needed.

- Replacements: Plan for periodic replacement of rollers or motor components.

- Cleaning: Remove debris, especially in sanitary settings.

Pricing of Heavy Duty Powered Roller Conveyor

- Range: $3,000–$15,000+ per 10'–20' section.

- Basic chain-driven (48" wide): $3,000–$7,000.

- Advanced with controls: $8,000–$15,000.

- Factors: Roller size, motor power, drive type, and customization (e.g., sensors, curves).

- Additional Costs: Maintenance ($200–$500/year) and electricity.

Integration of Heavy Duty Powered Roller Conveyor

These conveyors can enhance operations when paired with:

- Automated Guided Vehicles (AGVs): For seamless load transfers.

- Warehouse Management Systems (WMS): To optimize inventory flow.

- Sortation Systems: For automated sorting of heavy items.

Choosing the Right Heavy Duty Powered Roller Conveyor

- Load Requirements: Define weight (e.g., 2,000 lbs), size (e.g., 48" x 40"), and stability.

- Drive Mechanism: Chain-driven for heavy loads; belt-driven for smoother operation.

- Motor and Controls: Match power (e.g., 2 HP) and controls (e.g., VFD) to your needs.

- Environment: Consider layout (straight or curved) and conditions (dry or washdown).

- Budget: Weigh initial cost against long-term savings (e.g., labor, efficiency).

Example

For a warehouse moving 2,500-lb pallets over 20':

- Specs: 54" wide, 3.5" steel rollers, chain-driven, 3 HP motor, 40 ft/min, steel frame.

- Cost: $10,000–$15,000.

- Suppliers: Hytrol, Dematic, or Made-in-China.com.

Heavy-duty powered roller conveyors are a reliable solution for moving heavy loads efficiently. With customizable features, durable designs, and integration options, they suit a range of industrial needs. Evaluate your load, layout, and budget to select the best system, and consider long-term benefits like reduced labor and improved safety. For a specific recommendation, share details like load weight or conveyor length!

Leave Me Your Requirement!